As we face an ever-growing global population and climate uncertainties, Controlled Environment Agriculture (CEA) is a glimpse into the food-secure future of farming. But, this isn’t your grandfather’s farming. CEA is a technology-based farming approach that monitors and optimizes crop growth conditions year-round, no matter the weather. Greenhouses, vertical farming and other hydroponic farming are all CEA examples in action. CEA is more than a trend — it’s the answer to present and future food production problems by surpassing traditional farming limitations.

Why is CEA gaining popularity today? Because it’s a way to meet our growing population demands. With an expected global population of nearly 10 billion by 2050, the need for food production will skyrocket. CEA offers a resource-efficient solution, minimizing water usage and reducing the need for vast tracts of arable land. By localizing food production, CEA reduces the carbon footprint for transporting and storing produce.

CEA farming is where agricultural precision and efficiency meet. It uses technologies to control indoor environmental factors like light, temperature, humidity and water nutrient delivery. This lets crops thrive even where traditional farming is impractical, like urban settings.

Let’s look at the types of CEA growing facilities that will pave the way to a sustainable, food-secure future.

What Are the Different Types of CEA Facilities?

The foundation of Controlled Environment Agriculture is its structural elements, mainly greenhouses, indoor grow rooms and vertical farms. As the name suggests, CEA facilities offer controlled environmental conditions crucial for maximizing crop growth and health. With meticulous control, CEA crop cultivation ensures precise customization, resource efficiency and profitable sustainability.

Another significant aspect of CEA facilities is space efficiency, addressing urbanization and population growth challenges. Innovations like vertical farming, aquaponics, and aeroponics are designed to maximize crop yield within limited spaces. As land resources become more precious, CEA’s space-efficient solutions offer promising alternatives to meet the needs of a changing world.

Here are the different types of Controlled Environment Agriculture growing facilities:

1. Greenhouses

As a pivotal type of CEA, greenhouses are enclosed structures with transparent walls and roofs, allowing sunlight in while retaining warmth. Greenhouse controlled environments let farmers adjust temperature, humidity and light, creating the perfect plant growth conditions. Greenhouses offer protection from adverse weather and pests and extend the growing season, making them a cornerstone of CEA.

2. Vertical Farming

A structural innovation in CEA, vertical farms leverage vertical space by stacking crop layers in a controlled setting. Unlike traditional horizontal farming methods, vertical farms typically stack layers of hydroponic or aeroponic systems that deliver nutrients by water or air. Vertical farms maximize space use, making them ideal for urban areas with limited land. The precision control in vertical farms over factors like light, temperature and humidity ensures optimal crop growth conditions.

3. Indoor Grow Rooms

Integral to CEA, indoor grow rooms are enclosed areas outfitted with artificial lighting, temperature control systems and precise irrigation setups. Indoor grow rooms tailor environmental conditions to meet the specific needs of plants, enabling year-round cultivation independent of climate limitations. Especially beneficial for high-value crops, indoor grow rooms ensure consistent, quality yields.

What are the Key Requirements for CEA Hydroponics?

In Controlled Environment Agriculture, achieving successful hydroponic growth and yield requires balancing factors like temperature, humidity, water quality and ventilation. These factors are monitored to work in harmony, fine-tune and stabilize indoor growing conditions, regardless of outdoor fluctuations. At its core, CEA farming customizes factors that cater to the needs of each growth cycle for consistent, sustainable and robust year-round crop production.

Here are the different requirements of Controlled Environment Agriculture hydroponics:

1. Temperature & Climate Control

The success of CEA relies on precise temperature and humidity control to promote plant growth, prevent diseases and ensure high-yield crop production. Advanced climate control systems, including heating, ventilation and cooling, are used to maintain optimal conditions. This regulated control eliminates the unpredictability of outdoor climate, creating a stable environment for crops. By providing a controlled and stable environment, CEA offers a reliable and efficient approach to agriculture.

2. Light Management

CEA light management is fundamental for plant growth, involving artificial lighting systems like LEDs or HID lights. Tailoring light spectra, intensity and photoperiods ensures plants receive the necessary light for photosynthesis and development. CEA lighting customizations provide specific light wavelengths to accommodate different growth stages. This precise light management allows growers to maintain consistent and strong crop production, regardless of external conditions. Customizing light is a key factor in the success of CEA systems, contributing to efficiency, predictability and overall success.

3. Soilless Agriculture: Types of Hydroponics

In modern agriculture, soilless farming marks a groundbreaking shift, breaking free from the constraints of traditional soil-based cultivation. Without the limitations of arable land and water scarcity, soilless farming introduces more sustainable and efficient farming approaches.

At the forefront of soilless agriculture techniques are hydroponics and aeroponics, each offering unique advantages.

What is Hydroponics?

Hydroponics, a term derived from the Greek words ‘hydro’ (water) and ‘ponos’ (labor), represents the new era of plant cultivation. Hydroponics uses a nutrient-rich water solution to nourish plant roots, employing inert growing mediums like perlite or coconut coir. Best-practice commercial CEA hydroponic systems often incorporate water reclamation strategies, recycling water to maximize efficiency and sustainability.

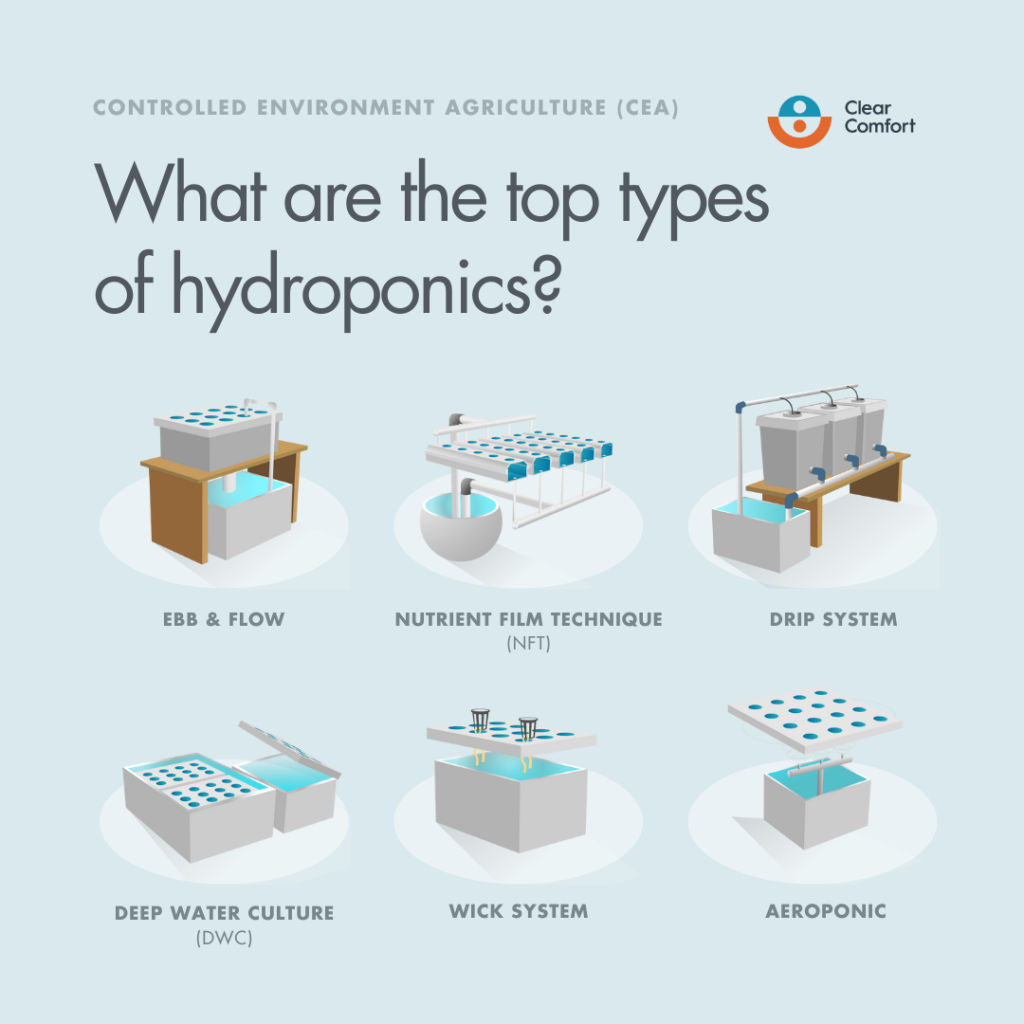

Here are the main types of hydroponics in CEA:

1. Nutrient Film Technique or NFT Hydroponics

Nutrient Film Technique or NFT hydroponic systems have a continuous flow of nutrient solution runs over the plant roots. This thin film of nutrients is only a few millimeters deep, which is why it’s called a “nutrient film.” Plants are usually placed in channels, and the nutrient solution is pumped to the high end of the channel and flows by gravity to the lower end, ensuring that the roots have access to nutrients 24/7.

2. Ebb and Flow Systems

Master the art of hydroponics with Ebb and Flow systems, the versatile choice for cultivators. This system works on a simple mechanism of flooding the grow tray with nutrient solution at regular intervals and then draining it back. It’s ideal for a variety of plants, especially those requiring periods of dryness. Known for their adaptability and efficient nutrient delivery, these systems provide a dynamic hydroponic growing environment, ideal for various plant types.

3. Deep Water Culture or DWC Hydroponics

Deep Water Culture or DWC hydroponic systems are a favorite for cultivating beginners and experts alike. Plants are suspended in a solution of nutrient-rich, oxygenated water. A platform, usually made of foam, holds the plants above the solution, allowing the roots to hang down into the water. Air pump aeration systems supply oxygen to the solution to prevent the roots from drowning, promoting rapid growth.

4. Drip System or Drip Hydroponics (Recovery or Non-Recovery)

Drip hydroponics uses drip system irrigation to precisely deliver water and nutrients directly to each plant’s root zone through drip irrigation lines. Hydroponic drip systems ensure water efficiency by delivering a slow feed of nutrient solution to the base of each plant through a network of tubes or pipes. In CEA, drip systems, in a recovery or non-recovery design, offer an effective way to manage water and nutrients. Recovery systems in drip hydroponics recirculate unused nutrient solution, enhancing resource efficiency. Additionally, non-recovery systems demand precise management to maintain the balance of the nutrient solution, highlighting the importance of drip system watering for plant health.

5. Wick Hydroponics

Wick system hydroponics is a simple method where a wick passively transports nutrient solution from a reservoir to the plant’s root zone. In a wick hydroponics, plants are placed in an absorbent substance, such as perlite or vermiculite. A wick runs from the planting container to a reservoir of nutrient solution. The nutrient solution travels up the wick and into the absorbent medium by capillary action, providing the plants with nutrients.

6. Aeroponics

Aeroponics suspends roots in the air, delivering nutrients through a fine mist. This method ensures well-oxygenated nutrient solutions, enhancing oxygen absorption, stimulating growth and increasing nutrient uptake efficiency. Aeroponics offers precise control over nutrient delivery, optimizing plant development.

4. Water Management, Treatment & Nutrient Delivery

In Controlled Environment Agriculture, water management plays an essential role, offering sustainable solutions to the challenges of water scarcity and pollution. By fine-tuning factors like humidity, temperature and fertigation, CEA feeds plants optimal water, minimizing waste, soil erosion, nutrient leaching and runoff. A prime advantage for CEA facilities is the ability to sustainably recycle water through water reclamation technologies and irrigation techniques.

1. AOP Water Treatment for Controlled Environment Agriculture

Facing criticism in the sustainability and profitability of Controlled Environment Agriculture, field operators are tasked with minimizing water usage and costs. The challenge? Restoring water quality for an unbroken water reclamation cycle of fertigation, dosing, nutrient delivery and reuse. The answer isn’t just any Advanced Oxidation Process (AOP), but a patented Hydroxyl-Based AOP water treatment technology with Dissolved Oxygen (DO) and Reverse Osmosis (RO).

An indispensable asset for CEA water efficiency, RO followed by Hydroxyl-Based AOP water treatment with DO oxidizes impurities in seconds – without the use or byproducts of chemicals like chlorine. This oxidation “resets” and perfectly conditions water for the seamless fertigation, dosing, nutrient delivery and reuse necessary for CEA water reclamation. Additionally, the AOP-driven approach eradicates pathogens, fostering a disease-free growing environment. By minimizing environmental footprint, chemical dependency and water quality troubleshooting, this advancement sets CEA facilities up for sustainability and profit.

2. Water Reclamation & Closed-Loop Systems in Controlled Environment Agriculture

CEA sustainability doesn’t end with AOP water treatment; closed-loop water systems aim to use every drop of water to its fullest potential. CEA water management often incorporates water reclamation with closed-loop systems. A closed-loop approach reduces freshwater demand while maintaining a consistent and high-quality water for plants. Combining precise irrigation, AOP water treatment with DO and closed-loop systems, CEA not only conserves water but ensures it’s utilized to the highest quality.

5. CO2 Enrichment systems

CEA growing facilities rely on various CO2 enrichment systems to optimize plant growth and maximize yields. Among the key components are CO2 generators, which introduce controlled amounts of carbon dioxide into the environment. These CEA systems continuously track CO2 levels to avert potential hazards or excessive concentrations that could adversely affect both plant and human health. Safety mechanisms, such as automatic shut-off features and alarms, are put in place to promptly address any deviations from the desired CO2 levels. Integrating these safety measures allows CEA operations to maintain a controlled and secure environment, protecting the crop and individuals within the facility.

6. Pest and Disease Control Systems

Pest and disease control is a critical component of CEA, ensuring healthy crop growth and high-quality yields. CEA Integrated Pest Management (IPM) techniques focus on proactive and eco-friendly strategies to minimize favorable conditions for pests and diseases. With controlled factors, CEA significantly reduces the risk of infestations and diseases, promoting a healthier plant environment and sustainable crop protection.

7. Automated Control and Monitoring Systems

CEA automated control and monitoring systems are crucial to optimize crop growth conditions. Real-time data monitoring CEA systems leverage sensor technology to accurately regulate environmental factors, such as temperature, humidity, light and pH levels. In essence, combining sensor technology and automated control systems is fundamental to CEA’s success, ensuring crops receive ideal conditions for growth and maximizing efficiency and yield.

Embracing the Future of Controlled Environment Agriculture

The future of Controlled Environment Agriculture isn’t just about high yields but also involves a comprehensive approach to agricultural resource efficiency, costs and operations. If you own or operate a CEA facility, conduct an in-depth cost analysis to identify opportunities to optimize energy, water, labor and materials. As a new and evolving industry, new technologies present new opportunities to drive CEA profitability and sustainability. Keeping up-to-date with the CEA industry is vital for understanding crop demand, forging strong buyer relationships and steadying your market presence.

Beyond industry insight, build a robust brand identity for your CEA production using effective marketing strategies to help differentiate products, command premium prices and cultivate a loyal customer base. Quality assurance fosters trust and customer loyalty, while sustainability practices curtail costs and appeal to eco-conscious consumers. Exploring diversification options, such as cultivating various crops or adding value to products, bolsters financial stability and taps into multiple revenue streams.

By leveraging the potential of CEA and strategically navigating its complexities, growers can achieve environmental sustainability and financial success, providing high-quality crops efficiently and contributing to a sustainable, food-secure future.